Exploring the Benefits of Metal Scrap Baling Presses

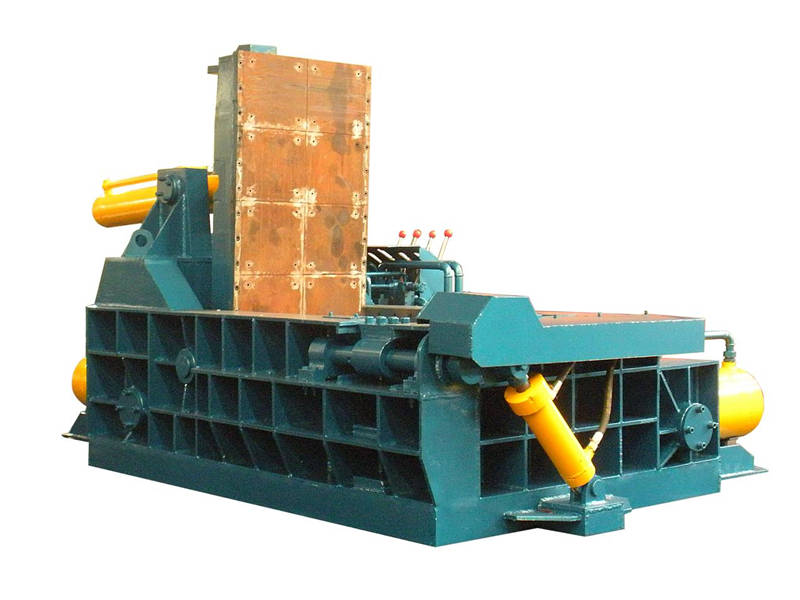

Metal scrap baling presses serve a crucial role in scrap metal recycling and disposal. These machines compact large volumes of scrap metal into smaller, high-density bales, making scrap metal significantly easier to handle, transport, and process. Here, we delve into the functionality, principles, and uses of metal scrap baling presses.

Functionality and Performance:

Metal scrap baling press is engineered with superior performance in mind. Utilizing tremendous force, these machines are able to condense bulky scrap metals into easy-to-handle bundles. This is particularly beneficial in industries that deal with substantial amounts of metal waste.

The efficiency of these machines is unmatched, as they swiftly process and bale scrap metals, greatly improving the productivity of a recycling or disposal operation. Many presses also come equipped with technologically advanced features such as automatic cycle control, which further simplifies and speeds up the baling process.

Understanding the Principle:

The operating principle of a metal scrap baling press involves three integral steps: compaction, consolidation, and baling. Metal scrap is first compressed under high pressure to reduce its size. The compacted material is then consolidated to form a solid mass. The last step involves binding the dense mass with bale ties or strapping, producing a bale that is easy to handle and transport.

Applications of Metal Scrap Baling Presses:

Metal scrap baling presses have a wide range of uses in numerous industrial areas. They are essential in scrap metal yards, waste recycling centers, as well as manufacturing industries that generate a sizable amount of metal waste, such as automotive, electronics, and construction industries.

In terms of environmental sustainability, these machines contribute decisively by recycling scrap metal, thus reducing landfill use, conserving natural resources and minimizing CO2 emissions.

In conclusion, metal scrap baling presses hold undeniable benefits in various industries. Whether it’s increasing operational efficiency, improving waste management, or contributing to environmental conservation, these machines play a vital role in the overall chain of scrap metal recycling and disposal.

Using a selection of relevant keywords throughout our exploration of the benefits of metal scrap baling presses, we’ve purposefully structured this article to be SEO-friendly, making it more discoverable for users searching for in-depth insights on this topic.